CS3-63-BK10-55-27-C1-030-J3-8-K-DST-SSP

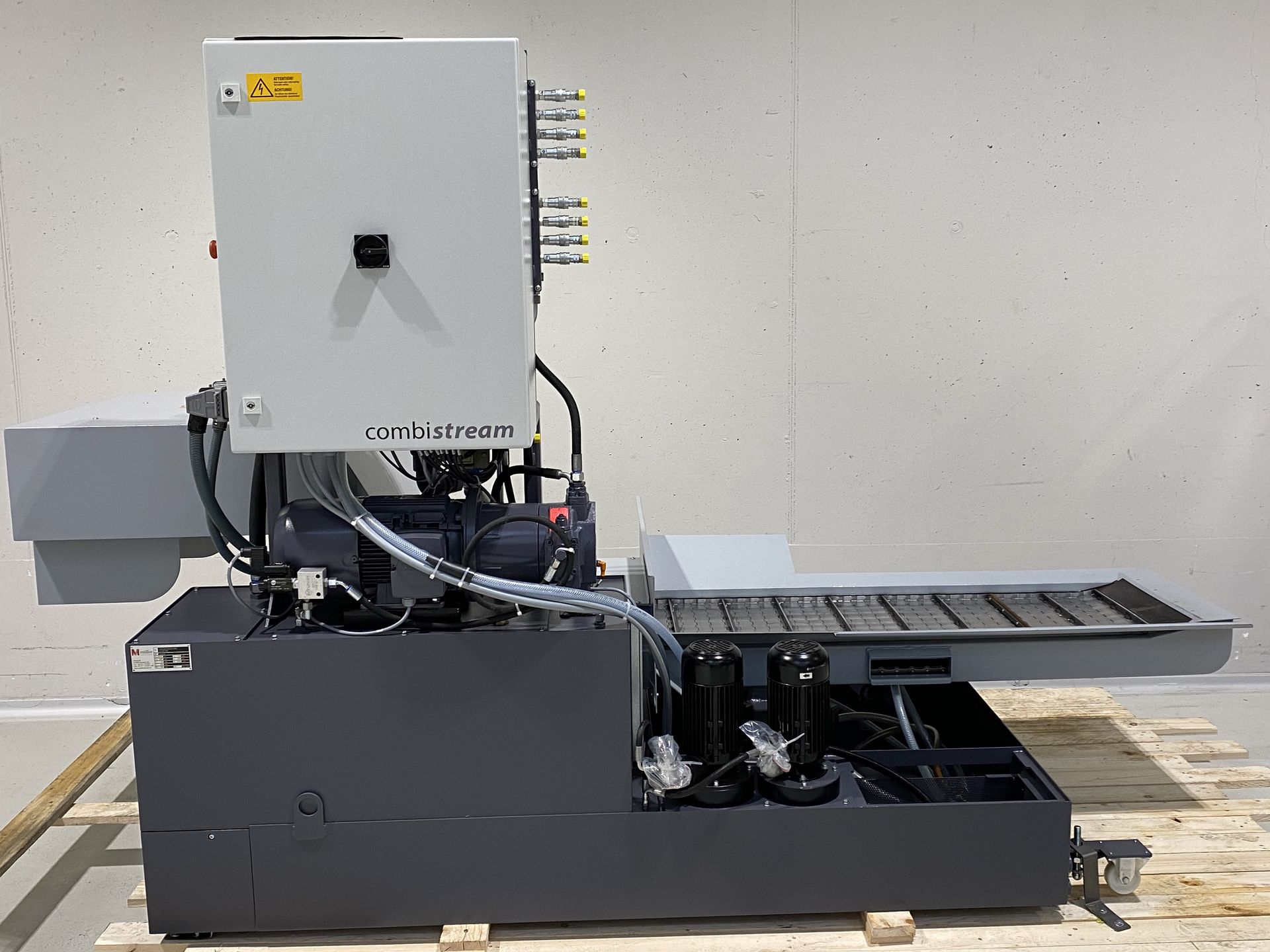

Chip conveyor, filter and high-pressure system all in one!

For Star SR38

Customs tariff number: 8479.8997

Colour: RAL 7015 and RAL 7040 structure finish

Technical data

============================

Q = 27 l/min

pmax = 110 bar

P = 5.5 kW

Serv. con. = 8 ( controllable)

Technical data (low pressure)1:

=========================================

Q = 100 l/min

P = 0.75 KW

p max. = 2 bar

Technical data (low pressure)2:

=========================================

Q = 50 l/min

P = 0.75 KW

p max. = 3,2 bar

Technical data (spindle flushing pump):

======================================

Q = 20 l/min

P = 0.75 KW

p max. = 2.5 bar

Operating medium: cutting oil

Viscosity requirements: machining oil 15-22 mm²/s; deep drilling oil 5-8 mm²/s

Technical description

The combistream system consists of a tank, a chip conveyor and an integrated technical unit for high-pressure and bypass filtration. The appearance and the detailed system setup are shown in the attached drawing. The tank replaces the original machine tank and is placed under the machine tool. High-pressure system supply takes place from a clean liquid tank mounted on the system. The high-pressure pump with eco+ control technology ensures constant low heat input by mechanically adjusting the flow rate to the tools' operating requirements. The working pressure can be adjusted progressively by means of a manual control (optionally also automatically via the machine program). Priming of the low-pressure pump takes place from the machine tank. The coolant is delivered directly to the machine loads via one direct or several controllable high-pressure service connections. The seal between the chip conveyor box and the interior of the machine is sufficiently tight to ensure that as many chips as possible fall directly onto the conveyor belt. The work space conveyor is designed as hinge belt. The contaminated medium and the residual chips flow from the working space conveyor through a retention strainer basket with high mesh density into the tank. The strainer basket must be emptied manually. The emptying intervals should be based on the degree of contamination of the machine. Any chips remaining on the hinge belt conveyor are removed automatically. Chip guide plates in the tank are designed to prevent that too many residual chips reach the suction area of the pumps. The coolant is drawn from the machine tank by a filter feed pump and delivered through a self-cleaning automatic filter into the clean liquid tank. During its non-productive times, the automatic filter also cleans the machine tank. The residues of the filter cleaning are discharged directly onto the working space conveyor. The predefined pressure steps option makes it possible to call up via the machine program specific pressures adjusted to the machining process. A separate low-pressure pump is mounted on the clean liquid tank for counter spindle flushing. This allows the counter spindle to be flushed with clean medium at low pressure. The system disposes of an electrical control which enables self-sufficient operation. A 46-pole Harting plug (star XS950-III) is the interface to the machine. Power supply is provided by means of a separate 6-pole Harting plug (20A). Electrical connection: 400V 3~/PE 50Hz.

Components of the device

============================

mobile combistream system unit on metal tank consisting of:

- pressure-controlled high-pressure pump Eco+ (smooth adjustment)

- pressure gauge

- touch panel for system operation

- easy-to-access maintenance openings

- work space conveyor as hinge belt conveyor

- removable strainer basket at the box drain in the machine tank

- chip wiper at the release

- Vulkollan slider at the bottom of the box

- controllable service connections (8)

- self-cleaning automatic filter 030 µm filtration efficiency

- bypass filtration of the machine tank

- filter feed pump

- Pressure control via machine program

- Spindle flushing pump

- electric filter contamination monitoring

- Emergency Stop button

- electronic control

- 5m connecting cable

Interested?

Please give us a call or send us an email. We are looking forward to helping you.

phone: +49 (0)741 - 174 575 - 0

info[at]muellerhydraulik.de