High-pressure system combiloop CL4G-800

A STANDARD - HIGHLY CUSTOMISABLE UP TO 300 L/MIN. AT A MAXIMUM OF UP TO 300 BAR

Do you need high rinsing performance? Do you also have fine chips and a high level of contamination on the machine? Is the highest surface quality your standard? Then the combiloop CL4G is a must. The CL4G-800 offers you a clean tank with a capacity of 800 litres in the comfort range, which contributes to a stable behaviour of the medium and a more uniform temperature environment. The standard version is equipped with full-flow filtration and, thanks to its clever modularity, can be perfectly customised to your requirements in terms of process-reliable filtration, rinsing performance and cooling. An automated sludge discharge for high flushing performance is available as an option. In the full expansion stage, for example with an integrated active cooler up to 12.0 kW, pressure control and up to four freely combinable high, medium and low pressure pumps, it sets new standards in terms of space utilisation and performance. And not to forget: it also looks good!

Already in multiple use worldwide on machine tools from the following manufacturers:

Benzinger, Biglia, Brother, Bumotec (Starrag), Chiron, Citizen, DMGMORI, Fanuc, Hermle, Index, Kitamura, Manurhin, Mazak, Nakamura, Okuma, Pfiffner, Schütte, Star, Tornos, Traub, Tsugami, Willemin-Macodel, and many more.

TECHNICAL DATA

| Feature | Design | |

|---|---|---|

| Equipment |

| |

| Delivery rate depending on configuration |

| |

| Pressure (some configuration examples, extract only) | Three pumps:

| |

| Filter / filter fineness |

| |

| Operation |

| |

| Useful connections |

| |

| Electrical interface |

| |

| Features |

| |

| Optional extras |

| |

| Machine contamination level more | Our recommendation for:

| |

ADVANTAGES AND HIGHLIGHTS

eco+ Dynamic Power Concept

- Infinitely variable in the high-pressure control range from 0 to 120 l/min; high energy efficiency

- Ideal control pump concept for maximum flexibility

- Low heat input

- Reliable processing

- Reduction of rejects, increase in output quality

- Better ecological footprint

- Reduction in operating and electricity costs

- High-quality, durable pumps

Full-flow filtration in the smallest space

- Automated production thanks to low-maintenance automatic filter; sustainable

- Full-flow filtration

- Sludge discharge into integrated sludge box or via automated sludge discharge into chip bucket (emptied during operation and a maximum of once per shift)

- No consumables, no hazardous waste

Clever modular system with the highest standards

- One system concept - all processes

- Up to three high-pressure pumps or combination of high, medium and low pressure

- Industry 4.0 safety features to prevent machine downtime

- Safety: flow monitor as standard

- Plate heat exchanger (cooling) inside (option)

- Highly compact active cooler up to 12.0 kW inside or can be retrofitted at any time (option)

- Serves all common cooling lubricants

Ingenious, well thought-out design

- Medium-free filtration without any filter changes

- Accessibility: high operating and service ergonomics

- Lightweight, removable inspection panels: extremely compact installation

- Smallest footprint in the performance class

- Large 800-litre clean tank

- Safety, professionalism, durability

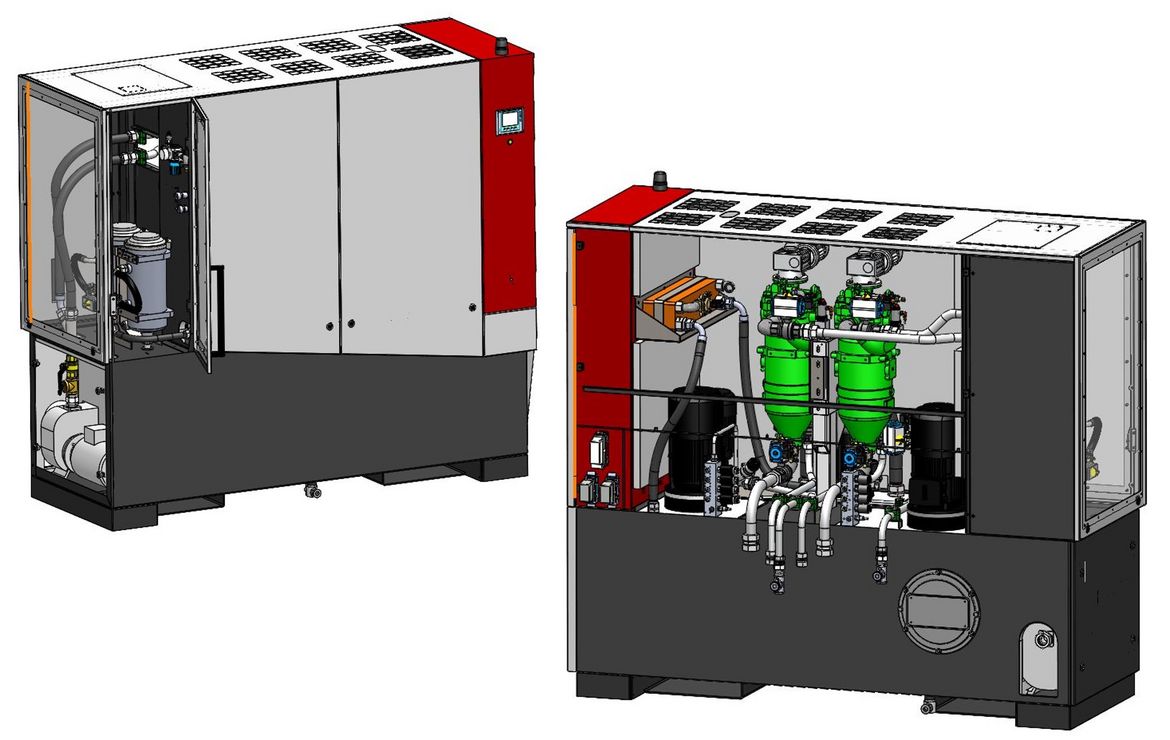

FUNCTION

Caption:

- Clean tank

- Centrifugal pump for filter circuit

- Self-cleaning automatic filter (optional)

- Sludge box with collecting sieve basket for filter sludge

- Return pump, sludge box (option)

- Off-line filtration (option)

- eco+ high-pressure pump with regulating pump technology / low-pressure pumps (according to pump configuration)

- Valve block with switchable outlets

- Cooling circuit pump (option)

- Cooling system / plate heat exchanger (option)

- Drain tap

- Electric control unit with touch panel for system operation

| Function and description of the combiloop CL4 G-800 high-pressure system |

| The combiloop CL4 G-800 is a high-pressure system that can be used for a wide range of applications. Mounted on a clean tank with a capacity of 800 litres, the pump systems can work as a full-flow filtration system in combination with the best possible filtration system. The system is completely enclosed in a modern, metallic design to protect it from dirt and external influences. A maximum of four supply pumps, consisting of high-pressure, medium-pressure and low-pressure pumps, are installed. A pressure-regulated pump is used to generate high pressure. It supplies the consumable tools in the machine with exactly the volume flow that they require at the preset working pressure for the respective machining operation. This enables efficient energy utilisation and avoids additional heat generation (eco+). The desired working pressure is infinitely adjustable. The cooling lubricant is channelled directly to the consumers via direct or switchable high-pressure outlets. All pump systems are supplied from the clean tank. The cooling lubricant is drawn from the machine tank by a dirt-resistant filter feed pump and fed into the clean tank via a self-cleaning automatic filter. The filter is cleaned automatically via the measured differential pressure. The sludge is rinsed out into the integrated sludge box, which must be cleaned occasionally by the operator. This cleaning process can take place during the ongoing production process without the machine having to be stopped. A return pump transports the medium from the sludge box back into the machine tank. When using double automatic filters with very high flushing capacities, the sludge is automatically discharged into a chip bucket. Thanks to the electrical control system, the system can be operated autonomously. Components of the appliance

|

DOWNLOADS