combiloop CL5

TAILORED POWER COOLING LUBRICANT SYSTEM

Your products are characterised by high precision and perfection? Your processes are clocked from beginning to end? Your cooling lubricant system must be perfectly tuned? Offering a flushing capacity of 300 liters a minute, automatic filtration, automated sludge discharge, user configurable pump parameters, high-pressure tool actuation, and optional medium temperature regulation, the combiloop CL5 leaves no wish unfulfilled.

Suitable for lathes by:

Citizen, DMG Mori, Manurhin, Star, Tornos, Tsugami, to name but a few.

| Technical Data | |

|---|---|

| Equipment |

|

| Flow rate |

|

| Pressure |

|

| Filter / Filter fineness |

|

| Operation |

|

| Service connections |

|

| Degree of machine contamination more |  |

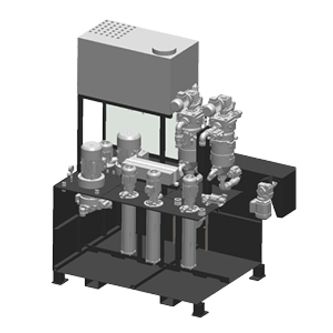

FUNCTION

Caption:

- Clean liquid tank

- Reciprocating pump for filter cycle (not visible)

- eco+ high-pressure pump with self-regulating piston pump technology

- Low-pressure pumps for flood cooling

- Low-pressure pump for Niagara flushing

- Low-pressure pump for cover flushing

- Level and temperature sensor

- Self-cleaning automatic filter combination for full flow

- Collecting chamber for filter sludge (not visible)

- Automated sludge discharge (option)

- Touch panel for system operation (not visible)

- Valve block with controllable service connections (not visible)

- Plate heat exchanger (option)

- Cooling system (option)

- Electronic control (not visible)

DOWNLOADS

Interested?

Please give us a call or send us an email. We are looking forward to helping you.

phone: +49 (0)741 - 174 575 - 0

info[at]muellerhydraulik.de

News

THE NEW COMBILOOP CL3 G – BEST-IN-CLASS IN COMPACT HIGH PRESSURE

A critical insight– expert interview with WB Werkstatt + Betrieb

Newsletter 2/21