Scraper belt conveyor chipstream CST1

ALL-ROUNDER CHIP CONVEYOR MADE IN GERMANY

Highly aesthetic, highly functional and particularly robust, the new Müller chip conveyors enrich modern production. With features including a clever anti-chip coalition, integrated oil mist extraction, intelligent control technology for process-optimised adaptation "at a touch" and integrated pre-separation via an overhead slotted screen, they provide the decisive, continuous increase in process reliability and chip removal. The motto is: genuine workmanship for your workmanship.

Suitable for lathes from:

Citizen Cincom and Miyano, Star and Tornos

TECHNICAL DATA

| Characteristic | Version | ||

|---|---|---|---|

| Equipment |

| ||

| Conveyor type |

| ||

| Operation |

| ||

ADVANTAGES AND HIGHLIGHTS

Perfect pre-separation due to balanced combination

- Optimum chip discharge, thanks to top-mounted slotted screen 1000 µm (500 µm option)

- Anti-chip belt, maximum discharge

- Can be combined with long parts discharge

Highly aesthetic and highly functional

- Timeless and high quality

- Operating and service ergonomics

- Long-lasting investment

In-house production of all sheet metal parts

- Precision and accuracy

- Certified quality

Option: Innovative and intuitive cycle time control

- Reduction of wear

- Efficient machining

- Improved process stability

- Industry 4.0

Particularly robust

- Solid and safe

- Durable and therefore sustainable

- Investment security

High process reliability

- Overflow protection

- Avoidance of cleaning work and production downtime

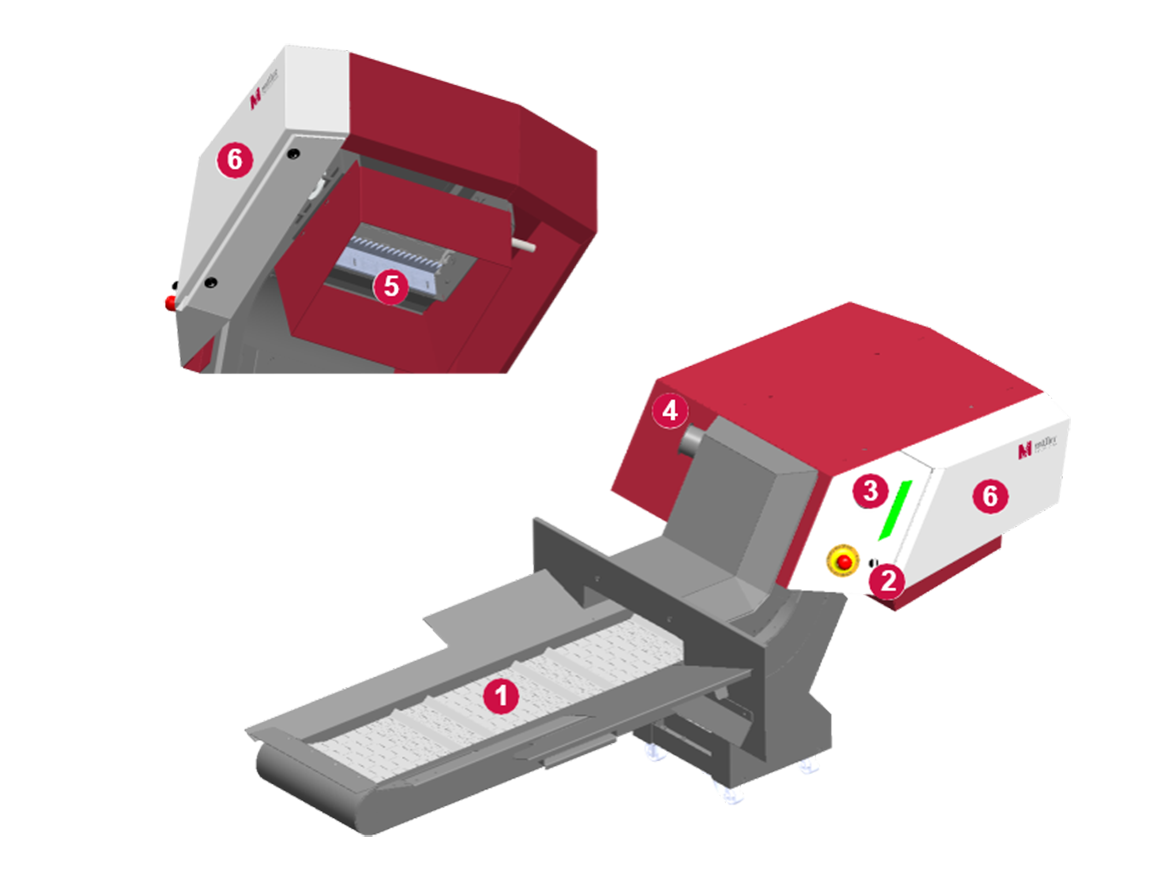

FUNCTION

| Function and description chipstream CST1 as scraper belt conveyor |

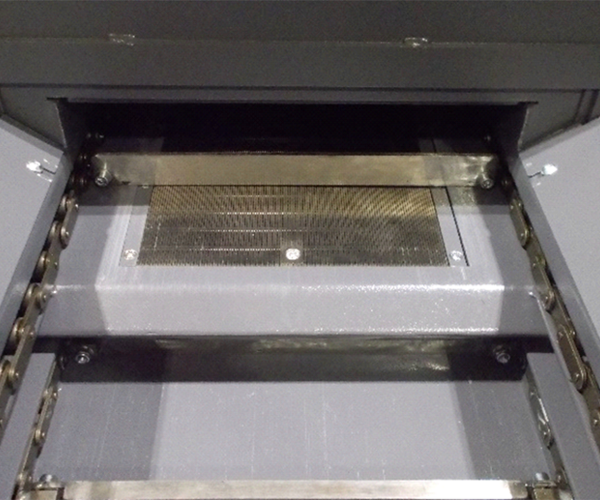

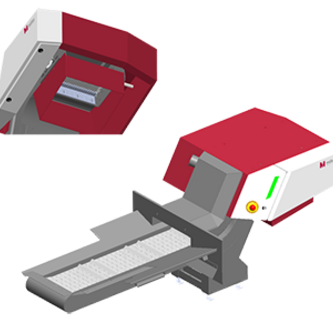

| The chip conveyor is a system consisting of a chip conveyor with an integrated technology unit for the control system. Please refer to the enclosed drawing for the appearance and exact design. The original machine tank is not replaced. The chip conveyor cassette seals with the machine interior so that as many chips as possible fall directly onto the conveyor belt. The work area conveyor is designed as a scraper belt conveyor. The medium flows from the work area conveyor via an overhead 1000 µm slotted screen into the machine tank (500 µm available as an option). The residual chips not retained by the slotted screen and discharged directly are collected by the machine's original retention screen basket. The screen basket must be emptied manually. The frequency depends on the degree of soiling of the machine. The chips remaining on the scraper belt conveyor are automatically discharged into the chip bucket via the scraper belt. The system is equipped with an electrical control system. The interface is still to be defined. Components of the device

|

DOWNLOADS