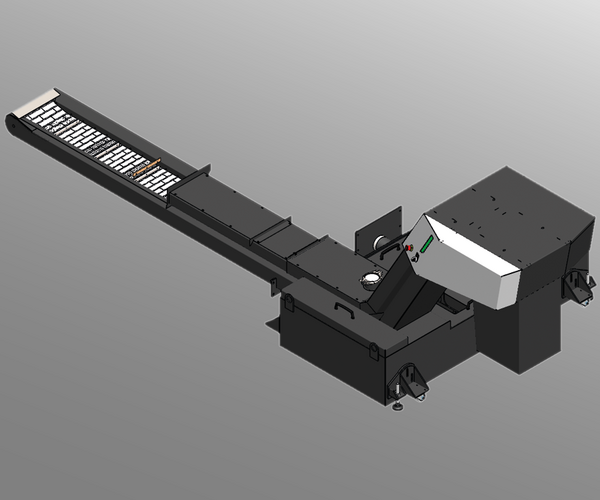

Combi conveyor with additional tank chipstream CST2

CHIP CONVEYOR ALL-ROUNDER WITH ADDITIONAL TANK AND DOUBLE CONVEYOR

Highly aesthetic, highly functional and particularly robust, the new Müller chip conveyors enrich modern production. With a clever anti-chip coalition, integrated oil mist extraction, intelligent control technology for process-optimised adjustment "at a touch" and a perfectly balanced anti-overflow perforated belt in conjunction with an additional tank, they provide the decisive, continuous increase in process reliability and chip removal. The easily accessible additional tank offers the great advantage of having more cooling lubricant volume in circulation, but at the same time provides even better chip management, as the chips in circulation that could not be discharged directly from the conveyor can be collected again in the additional tank. The chipstream CST2 is also characterised by the option of installing an additional pre-separation screen with up to 250 µm pre-separation in order to ensure that the retained chips are discharged into the chip container and thus keep the level of contamination in the machine as low as possible.

Suitable for lathes from:

Citizen Cincom and Miyano, Star and Tornos

Technical data

| Characteristic | Version | ||

|---|---|---|---|

| Equipment |

| ||

| Conveyor type |

| ||

| Operation |

| ||

ADVANTAGES AND HIGHLIGHTS

Additional tank as standard

- Increased cooling lubricant quantity

- Additional chip control in the additional tank

- Increased combinability of chip conveyor technologies

- Increased protection of the machine tank against rapid contamination

Anti-chip coalition: chip rake, Vulkollan ® driver and scraper, anti-chip border

- Optimum chip discharge, maximum difficult re-feeding

- Anti-chipping border, maximum discharge

- Can be combined with long part removal

Highly aesthetic and highly functional

- Timelessness and value

- Operating and service ergonomics

- Long-lasting investment

In-house production of all sheet metal parts

- Precision and accuracy

- Certified quality

Option: Innovative and intuitive cycle time control

- Reduction of wear

- Efficient machining

- Improved process stability

- Industry 4.0

Welded without distortion, particularly robust

- Solid and safe

- Durable and therefore sustainable

- Investment security

Innovative mixed hinged belt consisting of closed and perforated panels

- Overflow protection

- Avoidance of cleaning work and production downtime

| Function and description of the chipstream CST2 chip conveyor with additional tank and combination conveyor |

| The chipstream chip conveyor is connected to the existing machine tank of your machine tool. The chip conveyor cassette seals perfectly with the machine interior so that the chips fall as directly as possible onto the conveyor belt. The upper conveyor is designed as a hinged belt or scraper belt conveyor. The contaminated medium runs from the upper chip conveyor together with the fine chips into the lower scraper belt conveyor, which is separated from the additional tank by a pre-separation slotted screen. Scraper lips and brushes clean the slotted screen and convey the residual dirt into the chip bucket. Both conveyors have their respective discharge into a common chip bucket. Chip deflectors and, depending on the machine model, additional collecting baskets for chips in the additional tank prevent too many chips from entering the tank area of the machine tool and thus considerably increase the tank service life. The low-pressure pump draws from the machine tank, which is therefore appreciated. The system has a simple electrical function control for the conveyor. Components of the device

|

| Work area conveyor as hinged belt conveyor or scraper belt conveyor: | |

| Design as slat-band conveyor | Design as scraper belt conveyor |

|

|

| Not included: |

|

DOWNLOADS