High-pressure system combiloop CL3E

THE MOBILE HIGH-PRESSURE UNIT RETHOUGHT!

With the world's first separable high-pressure unit, we are making machining even more sustainable for the future. Compactness and installation options enable perfect space utilisation. Proven high-performance technologies in the modular system, such as automatic filters and eco+ regulating piston pump technology, ensure optimised operating costs and increased output quality with pressures of up to 300 bar.

Already in multiple use worldwide on machine tools from the following manufacturers:

Benzinger, Biglia, Brother, Bumotec (Starrag), Chiron, Citizen, DMGMORI, Fanuc, Hermle, Index, Kitamura, Manurhin, Mazak, Nakamura, Okuma, Pfiffner, Schütte, Star, Tornos, Traub, Tsugami, Willemin-Macodel, and many more.

Technical data

| Characteristic | Version | ||

|---|---|---|---|

| Equipment |

| ||

| Flow rate |

| ||

| Pressure |

| ||

| Filter / filter fineness |

| ||

| Operation |

| ||

| Service connections |

| ||

| Features |

| ||

| Electrical interface |

| ||

| Options |

| ||

| Degree of machine contamination more | Our recommendation for:

| ||

Advantages and highlights

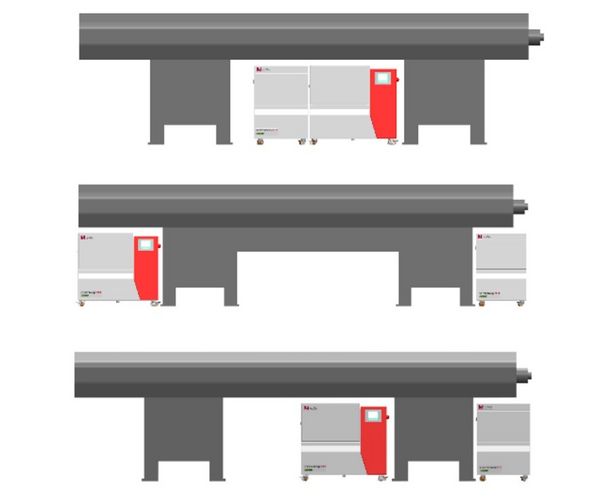

- Fits under almost all bar feeders

- Customisable modular system

- Safe investment: flexible use in the future too

- Space-saving compactness and flexibility up to max. 300 bar

- eco+ regulating pump technology with flow rate up to 27 l/min: Energy efficiency and lower heat input

- Easily accessible technology, simple and ergonomic filter change

- Advance warning for filter change for replaceable filter systems

- Flow monitor as standard + optional: adjustable flow monitor (max. 2 outlets)

- Integrated plate heat exchanger (cooling): Full and bypass

- Sludge box monitoring

- Fast amortisation

FUNCTION

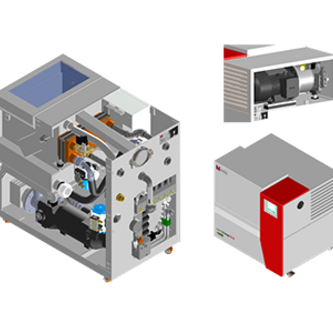

Caption:

- Functional unit in modern housing with 120-litre clean tank

- Filtration unit in modern housing

- Transfer pump for filter circuit

- Self-cleaning automatic filter (optional)

- Ball valve for off-line filtration (switches when clean tank is full)

- eco+ high-pressure pump with regulating pump technology

- Pressure adjustment

- Valve block with switchable outlets

- Collecting strainer basket for filter sludge

- Suction nozzle DN80

- Plate heat exchanger (optional)

- Touch panel for system operation

- Electrical control

| Function and description of the combiloop CL3 E high-pressure system |

| The combiloop CL3 E is suitable for particularly tight installation situations under the bar loader. It can also be positioned like a classic auxiliary unit next to the loader or lathe. The division of the combiloop into two parts creates incredible flexibility. The system can be set up and operated together or separately. It fits under almost all bar feeders, whereby the outer limits of the loader are generally not overbuilt even when placed separately. High pressure is generated by a pressure-controlled pump, which provides the consumer with exactly the volume flow required at the set pressure. This enables efficient energy utilisation and avoids additional heat generation (eco+). The working pressure is infinitely adjustable. The cooling lubricant reaches the consumers via one direct or several switchable outlets. A flow monitor is installed as standard; this continuously monitors the flow of cooling lubricant and can trigger an alarm if the flow falls below a minimum quantity. The modern, clearly recognisable function visualisation is provided by an LED light strip. Various filtration concepts are available - from alternating and double-switching to automatic filters. The automatic filter also cleans the machine tank during off-peak times. The filter is cleaned in the integrated sludge box for filter sludge. Specific pressures adapted to the machining process can be called up via the machine programme using the predefined pressure levels option. With the optional plate heat exchanger, the cooling lubricant can be cooled down and the temperature of the cooling lubricant kept stable within the scope of the technical possibilities and prevailing ambient temperature conditions. The medium is cooled continuously (full and bypass flow). A factory-fitted cooling water connection is required for this. |

DOWNLOADS