Control development

For us, the main tasks of the control system are intelligent utilisation of the high-pressure system and stable communication with the machine tool,

- to implement the requirements of the machinery directive and identify system errors, thereby ensuring the safety of the machine and the production process.

- to keep the production process as energy-efficient as possible thanks to intelligently designed control options (commands, parameterisation, etc.).

Electric filter clogging indicator

An integrated differential pressure switch measures the degree of contamination of the filter and an alarm is signalled to the machine when a certain value is reached.

Controllable service connections

On the machine side, you need as many free control codes (e.g. M functions) as switchable high-pressure outlets are required.

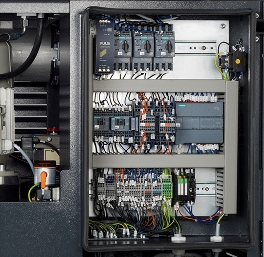

Electronic control

Constantly connected to the machine control system, this programmable logic controller is the brain of the cooling lubricant high-pressure system. It monitors the fill level in the clean tank, activates the high-pressure outlets sequentially or together as required, controls the feed pump, gives the command for automatic cleaning of the filter and communicates the operating status of the device.

Pressure control (mechanical / electronic)

- Pressure regulator at the high-pressure outlet - the simplest form of pressure control.

- If different pressures that can be freely selected via the machine programme are to be made available to a specific tool or tool turret, then combining several outlets into one or more high-pressure lines in the machine is the preferred variant. The selection is made via free control codes (e.g. M functions) in the machine.

- The third option is a stepless adjustment of the pressure directly via the machine programme. For this, the machine tool control system must be able to generate the corresponding commands.

Frequency-controlled drive

The speed of the pump's drive motor is changed here. The target speed can be determined via a command from the machine control system or simply via a specification on the high-pressure unit. This method allows the delivery rate to be adapted to the machining requirements. This type of control reaches its limits at low speeds, as the performance of standard asynchronous motors drops sharply at these speeds.