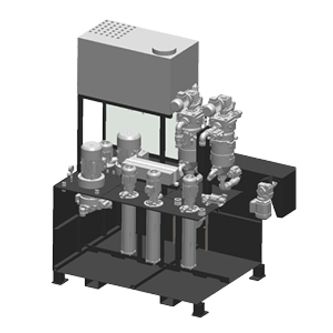

High-pressure system combiloop CL5

CUSTOMISED POWER COOLING LUBRICANT SYSTEM

Are your products characterised by high precision and perfection? Is your process sequence 100 % synchronised? Does your CL system need to be perfectly customised? With a flushing capacity of 300 litres per minute, automatic filtration, automated sludge discharge, a choice of pump configurations, high-pressure tool control and optional temperature control of the medium, the combiloop CL5 leaves nothing to be desired.

Suitable for lathes from:

Citizen, DMG Mori, Manurhin, Star, Tornos, Tsugami and many more.

TECHNICAL DATA

| Characteristic | Version |

|---|---|

| Equipment |

|

| Flow rate |

|

| Pressure |

|

| Filter / filter fineness |

|

| Operation |

|

| Service connections |

|

| Degree of machine contamination more | Our recommendation for:

|

FUNCTION

Caption:

- Clean tank

- Centrifugal pump for filter circuit (not visible)

- eco+ high-pressure pump with regulating pump technology

- Low-pressure pumps for flood cooling

- Low-pressure pump for Niagara flushing

- Low-pressure pump for cover flushing

- Fill level and temperature sensor (not visible)

- Self-cleaning automatic filter combination for full flow

- Collection chamber for filter sludge (not visible)

- Automated sludge discharge (optional)

- Touch panel for system operation (not visible)

- Valve block with switchable outlets (not visible)

- Plate heat exchanger (option)

- Cooling system (option)

- Electrical control unit (not visible)

DOWNLOADS