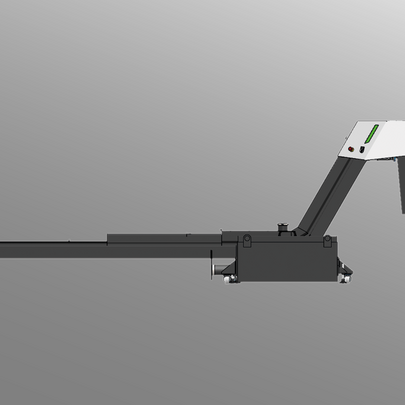

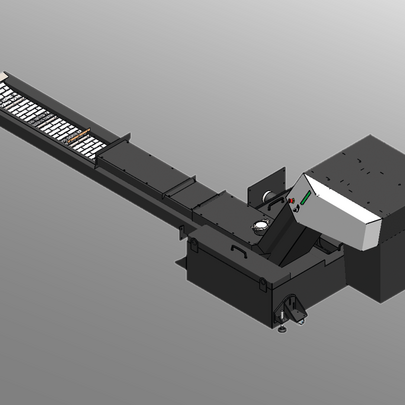

CHIP CONVEYOR WITH ADDITIONAL TANK CHIPSTREAM CST2

There are usually three different types of infeed conveyors: those with a magnetic hinged belt for ferromagnetic materials, those with a pure hinged belt and those with a scraper belt. Due to the machine tool-specific conditions under which we usually work, we have opted for two types and therefore offer a typical hinged belt conveyor with a split belt consisting of closed and perforated hinges, or alternatively a scraper belt conveyor with an overhead slotted screen. A successful extension of the possibilities is represented by slide-in conveyors with an additional tank. They have the same properties as conventional infeed conveyors, but offer additional benefits such as higher coolant availability, better control of chip removal and protection of the machine tank.

ADVANTAGES AT A GLANCE (depending on model)

Interested?

Please give us a call or send us an email. The Müller Hydraulik team will be happy to help you at any time.

Phone +49 (0)741 - 174 575 - 0

info[at]muellerhydraulik.de

What is a slide-in chip conveyor with an additional tank?

A slide-in chip conveyor with an additional tank is a special variant of a chip conveyor that is characterised by additional functions and advantages. While a conventional chip conveyor is mainly used to remove chips from the working area of a machine, the slide-in chip conveyor with additional tank goes one step further. The additional tank offers an extended capacity for holding chips and cooling lubricants. This enables a longer operating time without manual emptying and thus reduces the frequency of maintenance. The use of an additional tank also improves coolant availability and promotes more efficient use of resources.

This combined approach not only ensures a clean working environment, but is also a plus in terms of occupational safety, as loose chips can often pose a potential hazard to employees. A chip conveyor with an additional tank also has the advantage that a higher medium availability for cooling lubricants leads to more stable processes. Chip management can also be made even more controllable and process-reliable via the additional tank.

Chip conveyors are widely used in various industries, including the metalworking, automotive, aerospace and other metalworking sectors.