High-pressure systems Categories

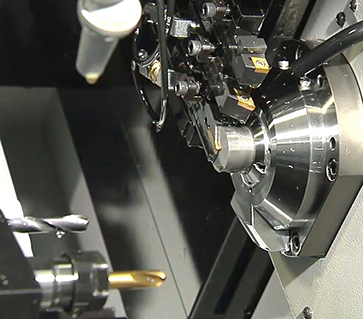

In wet machining, high-pressure systems clean cooling lubricant and feed it under pressure into the machine tool or the internally cooled tool(s). Müller high-pressure systems can be used on all types of metal and plastic cutting machines, e.g. sliding headstock automatic lathes, sliding headstock automatic lathes, single-spindle lathes, machining centres and multi-spindle machines. Advantages include 7 times longer tool life, up to 30 % lower part production costs, up to 40 % more output with higher quality and energy savings potential of up to 40 % compared to conventional technologies.

Advantages of Müller combiloop high-pressure systems

Function and problem solving

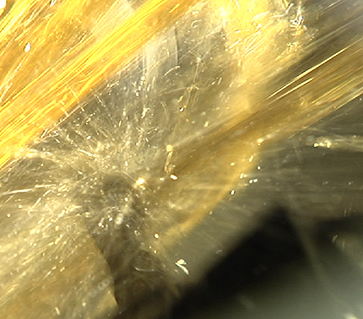

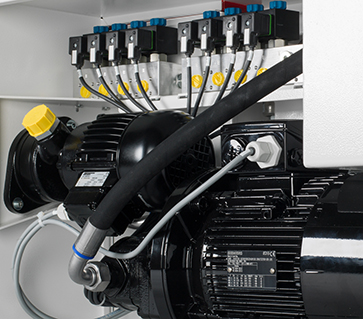

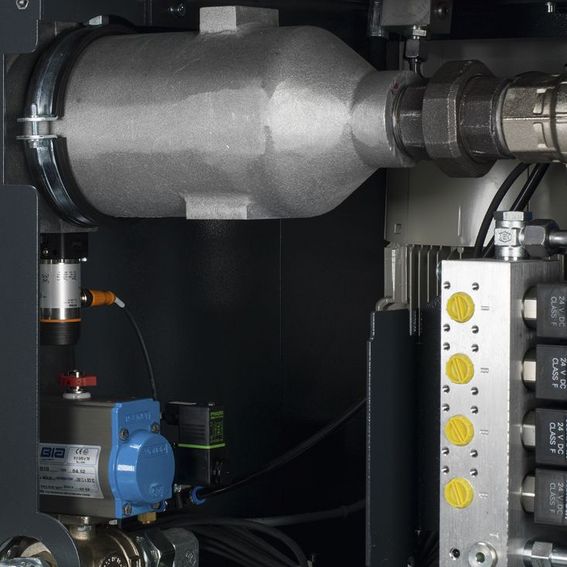

Müller high-pressure systems are particularly energy-efficient thanks to performance-optimised high-pressure technologies and the best filtration technologies. Chips are briefly broken by the use of high pressure above 30 bar. The advantages: The machining area and pick-up spindle remain chip-free. In addition, short-broken chips are easier to filter and dispose of.

| What does our high-pressure system do (function)? | Pressure range | Material | Müller high-pressure system |

|---|---|---|---|

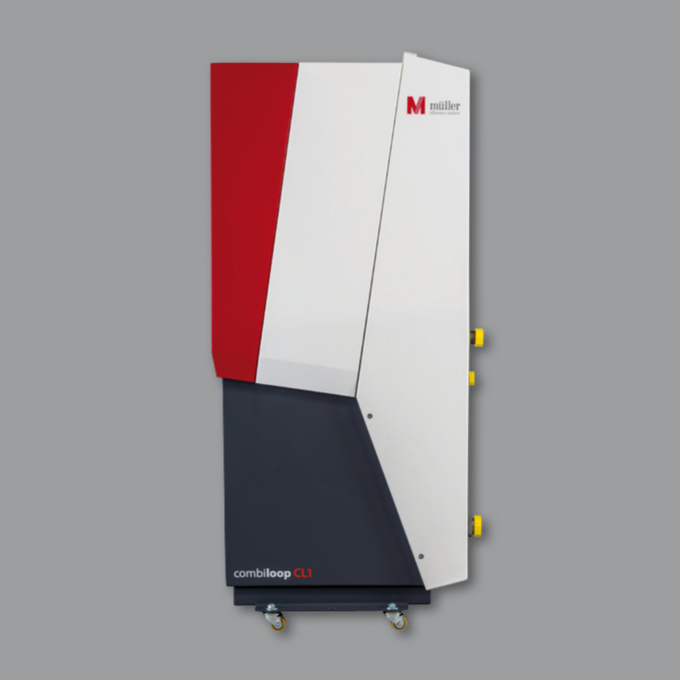

| < 70 bar |

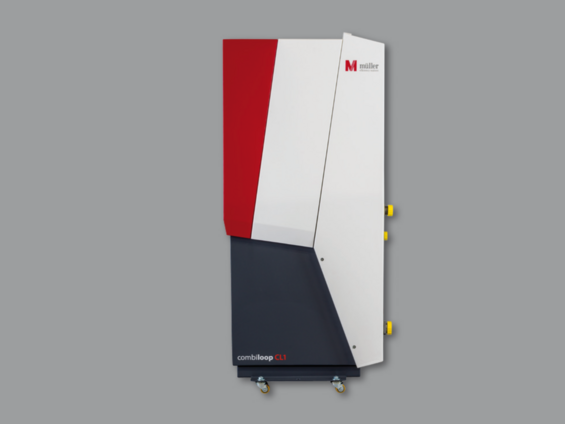

| combiloop CL1 E combiloop CL1 G combiloop CL2 E combiloop CL2 G combiloop CL3 E combiloop CL3 G combiloop CL4 G-400 combiloop CL4 G-600 combiloop CL4 G-800 |

| 30-70 bar |

| combiloop CL1 E combiloop CL1 G combiloop CL2 E combiloop CL2 G combiloop CL3 E combiloop CL3 G combiloop CL4 G-400 combiloop CL4 G-600 combiloop CL4 G-800 |

| 70-100 bar |

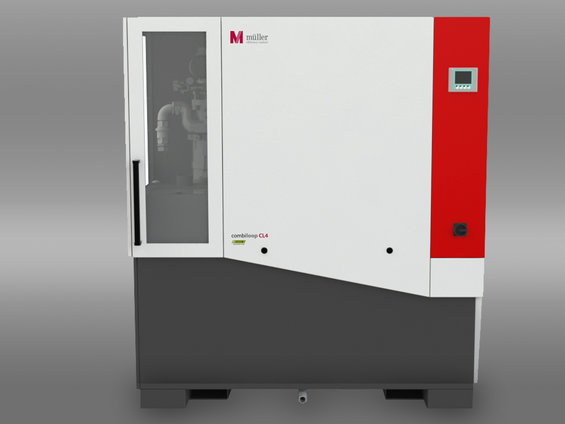

| combiloop CL2 E combiloop CL2 G ombiloop CL3 E combiloop CL3 G ombiloop CL4 G-400 combiloop CL4 G-600 combiloop CL4 G-800 |

| > 100 bar |

| comiloop CL3 E combiloop CL3 G combiloop CL4 G-400 combiloop CL4 G-600 combiloop CL4 G-800 combiloop CL5 |

*for drills with internal cooling

**lubricating materials can be machined well from 50 bar

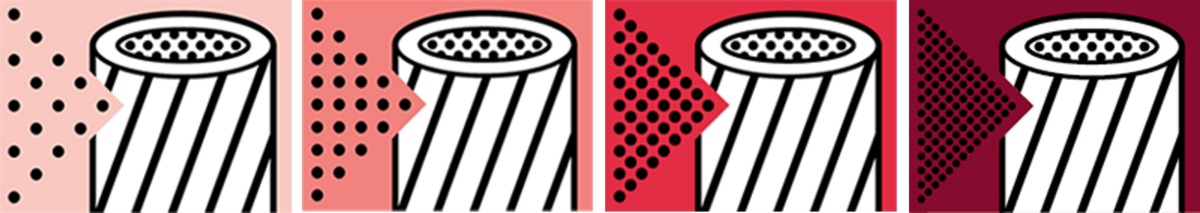

Degree of machine contamination

The requirements for a high-pressure system vary greatly depending on the degree of machine soiling. Our special symbols make it possible to determine the right high-pressure system at a glance, based on the degree of machine soiling.

Core competences + unique selling points

What is a high-pressure system?

In wet machining, high-pressure systems filter and clean cooling lubricant and channel it into the machine tool or internally cooled tools at pressures of 70 bar or more. Advantages: Increased efficiency, profitability, process reliability, tool life, quality, cutting and drilling speeds.