Chip conveyor technology

It is not uncommon for different materials to be processed and different types of chips to be produced on the same machine. The ideal solution would be to use the right chip conveyor for each type of chip. With combistream, we offer you modern chip conveyor technologies for a wide variety of chip types. Practical experience shows that the following three basic concepts are ideally suited to a wide range of application situations and can be implemented for various machine types. This does not mean that other chip conveyor technologies cannot be used in exceptional cases:

Basic concept 1

Work area conveyor as scraper or slat-band conveyor with large lubricoolant outlet and integrated chip collection basket below the outlet is very suitable for high chip volumes:

Work area conveyor as scraper or slat-band conveyor with large lubricoolant outlet and integrated chip collection basket below the outlet is very suitable for high chip volumes:

- high chip volumes.

- as few different materials and chip types as possible in order to determine chip conveyors in the best possible way.

- normal and medium degree of machine contamination due to rather large and coarse chips or readiness for increased dirt tank cleaning with very fine materials.

- Medium maintenance effort for the entire system (cleaning of the machine tank depending on the degree of soiling, but no more than once a month).

| Recommended for | Material | Chip conveyor |

|---|---|---|

| Normal and medium degree of machine contamination | Steels and hard alloys, different chips from long to short | Hinged belt conveyor (BK10) |

| High degree of machine contamination | Brass, aluminium and other very fine-chipping materials | Scraper belt conveyor (BK11) |

Basic concept 2

Work area conveyor as scraper or slat-band conveyor with large lubricoolant outlet directly into an integrated pre-separation via slotted screens with automated chip discharge via a scraper conveyor is very well suited for high chip volumes:

Work area conveyor as scraper or slat-band conveyor with large lubricoolant outlet directly into an integrated pre-separation via slotted screens with automated chip discharge via a scraper conveyor is very well suited for high chip volumes:

- high chip volumes.

- as many different materials and chip types as possible, so that the pre-separation principle can be used effectively.

- a medium degree of machine soiling, especially due to fine and floating chips. The aim is to avoid frequent cleaning of the dirt tank.

- Medium maintenance effort for the entire system (cleaning of the machine tank depending on the degree of soiling, but no more than four times a year).

| Recommended for | Material | Chip conveyor |

|---|---|---|

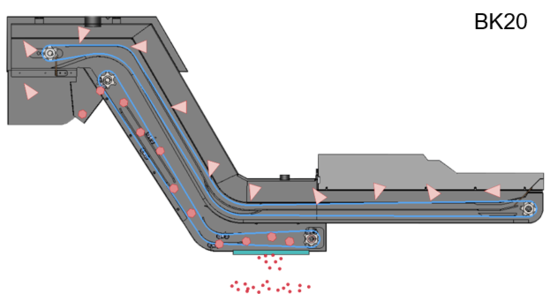

| Medium degree of machine contamination | Steels and hard alloys, different chips from long to short | Hinged belt conveyor (BK20) |

| Only fine and floating chips | Brass, aluminium and other very fine-chipping materials | Machine room: Scraper belt conveyor Dirt tank: Scraper belt conveyor (BK21) |

Basic concept 3

Work area conveyors as scraper or slat-band conveyors with a large lubricoolant outlet directly into the machine tank in combination with bottom cleaning of the machine tank by a scraper conveyor (usually in conjunction with full-flow filtration systems) are very suitable for high chip volumes:

Work area conveyors as scraper or slat-band conveyors with a large lubricoolant outlet directly into the machine tank in combination with bottom cleaning of the machine tank by a scraper conveyor (usually in conjunction with full-flow filtration systems) are very suitable for high chip volumes:

- high chip volumes.

- frequently changing materials, various chip types that can be discharged in the best possible way using basic concept 3.

- a high degree of machine contamination due to fine chips and sludge.

- specific to brass and aluminium, possibly plastics.

- Low maintenance requirements (cleaning of the machine tank depending on the degree of soiling, but no more than twice a year).

| Recommended for | Material | Chip conveyor |

|---|---|---|

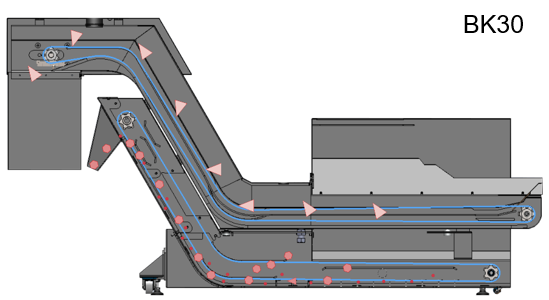

| All materials, all chip types, for frequently changing machining operations | Steels and hard alloys. Very different chips from long to short. Frequent material changes | Machine room: Hinged belt conveyor Dirt tank: Scraper belt conveyor (BK30) |

| Only fine and floating chips | Brass, aluminium and other very fine chip materials | Machine room: Scraper belt conveyor Dirt tank: Scraper belt conveyor (BK31) |

Frequency-directed belt control

All our chip conveyor models chipstream and combistream are equipped with a frequency converter, which ensures modern monitoring of the chip conveyor.

Advantages:

- Fewer mechanical wear parts

- Variable belt speed control

- Very flexible interval switching possible

- High level of user-friendliness

- Less oil discharge via variable belt control

- Clear visual communication with the operator via LED bar