High-pressure system combiloop CL1G

THE SPACE MIRACLE - FOR THE HIGH-PRESSURE BEGINNER

The attractively priced entry-level product in the combiloop family fits perfectly into the unused space between the bar feeder and the machine tool. Stylish and highly functional, it is the ideal solution for temporary pressure boosting with high pressure up to 70 bar and high-performance filters in terms of purity and service life. combiloop CL1 G was designed for flexible, efficiency-enhancing use on various machine tools.

Already in multiple use worldwide on machine tools from the following manufacturers:

Benzinger, Biglia, Brother, Bumotec (Starrag), Chiron, Citizen, DMGMORI, Fanuc, Hermle, Index, Kitamura, Manurhin, Mazak, Nakamura, Okuma, Pfiffner, Schütte, Star, Tornos, Traub, Tsugami, Willemin-Macodel, and many more.

Technical data

| Characteristic | Version | ||

|---|---|---|---|

| Equipment |

| ||

| Flow rate |

| ||

| Pressure |

| ||

| Filter |

| ||

| Filter fineness |

| ||

| Operation |

| ||

| Service connections |

| ||

| Electrical interfaces |

| ||

| Options |

| ||

| Degree of machine contamination more | Our recommendation for:

| ||

Advantages and highlights

Clever modular system with the highest standards

- Progressive up to 70 bar (robust gear pump with cast housing and noise damping as well as good pump efficiency class)

- Early chip breaking, spindle flushing, enables deep hole drilling

- Serves all common cooling lubricants

- Up to 10 times longer tool life

Ingenious, well thought-out design

- Quick filter change from above, without contaminating the clean area

- Electrical contamination indicator

- Lightweight, removable inspection panels: extremely compact installation, e.g. under the headstock of the machine tool

- Accessibility: high operating and service ergonomics

- Safety, professionalism, durability

Ingenious filter concept

- Long service life, significant reduction in operating costs

- Increased service life thanks to dynamic fine filter concept (up to 25 μm)

- Wire mesh: no polymer, reusable, cost-efficient, recyclable

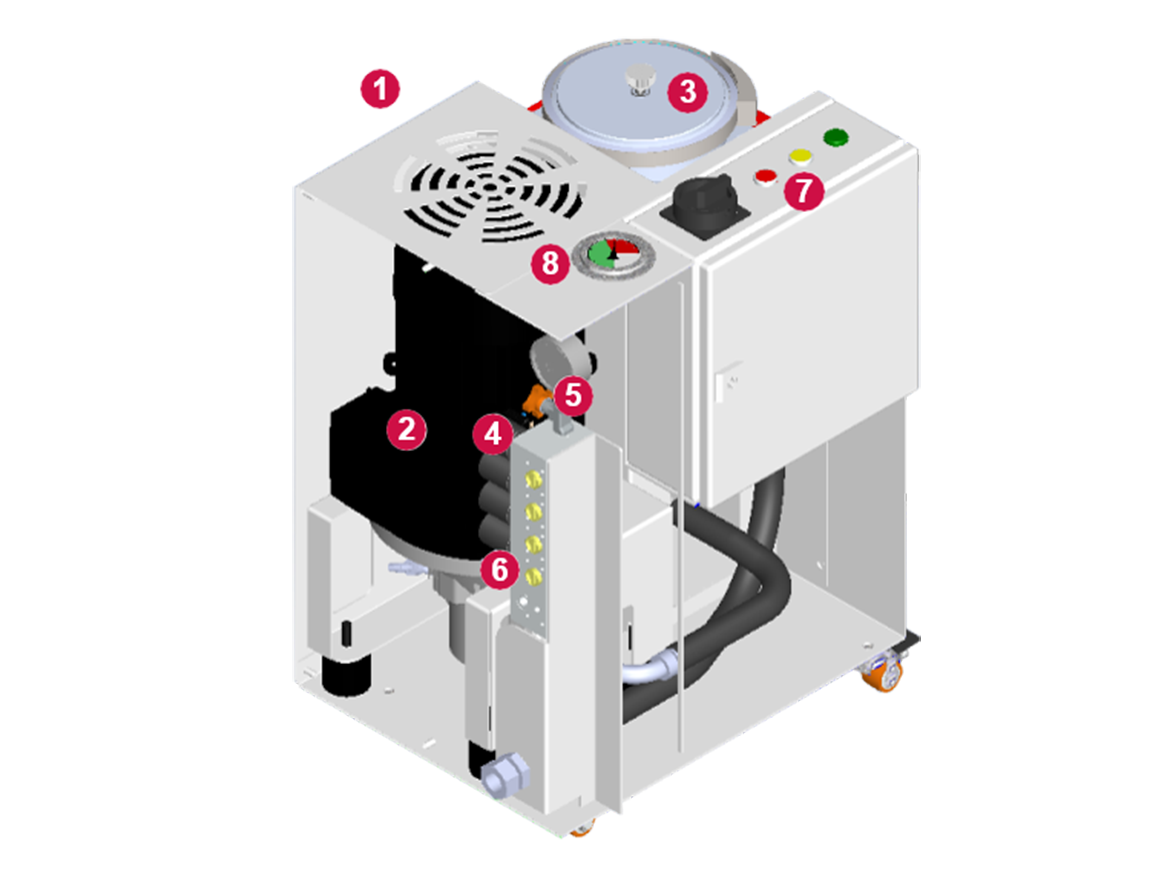

FUNCTION

| Function and description of the combiloop CL1 G high-pressure system |

| The combiloop CL1 G high-pressure system draws the contaminated medium from the machine tank of the machine tool with its own high-pressure pump through the integrated fine filter and supplies the machine's tools with cleaned cooling lubricant via the switchable high-pressure outlets. During the suction process, the suction nozzle should be positioned in the least contaminated area of the machine tank. Up to 4 switchable high-pressure outlets can be activated via M functions in the machine programme. The operating pressure can be set manually on the high-pressure system. If the filter is dirty, an alarm is triggered. To clean the filter, the machine must be stopped to replace or clean the filter element. Effective spindle rinsing via the high-pressure system is also possible using a pressurised high-pressure outlet. |

DOWNLOADS