It’s a familiar situation, and the problems are obvious: high pressure isn’t necessarily high pressure. When adding “high pressure” as an original feature to processing machines at the works, this often takes the form of integrated 20–30 bar pumps. This causes difficulties in operation or leads to the loss of potentials. “Both in these original equipment cases and in classic retrofitting, the processing machines or small lathes are often fitted with completely oversized high-pressure systems that pump flushing performances of 300 l/min – for processes that require 80–120 l/min at the most – and with non-performance-optimised technologies. It’s like using a sledgehammer to crack a nut, and it’s done at the expense of customer efficiency and profitability,” says Martin Müller, Managing Director of Müller, the European market leader for compact high-pressure on sliding headstock automatic lathes. “And this is exactly where we come in with our beautifully designed, high-performance combiloop compact units for high flushing performances.”

For the sake of process accuracy and to counter over-dimensioning, Müller also offers a clever modular system like it does for its special products for high flushing performances. Especially when it comes to matters of filtration technology, various concepts are possible – from the attractively priced cascading filters for combiloop CL4 G-400 eco+ 70/60 and combiloop CL3 G eco+ 50/45 or 70/40, to automatic filtration.

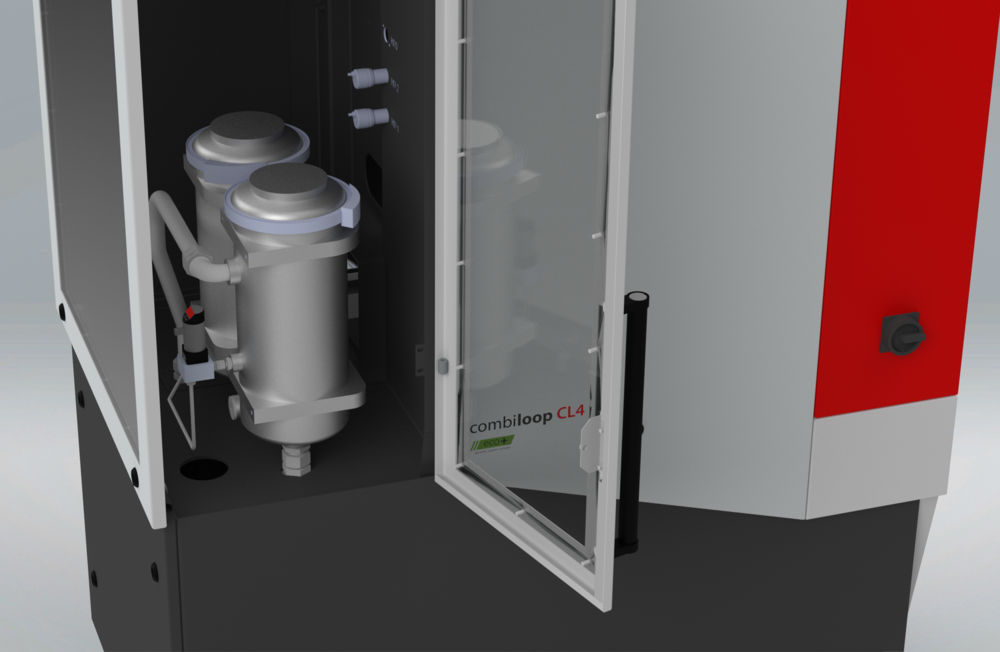

// combiloop CL4 G-400 eco+ 70/60 with cascading filtration

// combiloop CL4 G-400 eco+ 70/60 with cascading filtration

Two-stage cascading filtration saves consumables and reduces downtimes

When machining on processing centres, a very high chip volume is generated almost continuously. At the same time, high coolant flushing performances are required – but naturally with the corresponding purity in the desired high-pressure operation over 30 bar. As a financially and economically very interesting entry-level solution, Müller offers a two-stage cascading filter system consisting of pre- and fine filters for the combiloop CL4 G-400 eco+ 70/60, combiloop CL3 G eco+ 50/45 and 70/40. The medium first flows through a coarse pre-filter (mesh density approx. 500 μm). This produces a filter cake that increases the degree of separation and the filter fineness. In the second step, the pre-cleaned medium passes through the fine filter, achieving a purity of up to 25 μm in the two combiloop CL3 G models, and up to 40 μm in the combiloop CL4 G-400 eco+ 70/60. The solution offers another advantage over compact belt filters. The cascading filter uses washable filter elements, including large volume ones, which greatly reduces wear and the operating costs – and is much better for the environment. Plus the productivity time of the machine is increased.

// combiloop CL4 G-400 eco+ 70/60 with cascading filtration

// combiloop CL4 G-400 eco+ 70/60 with cascading filtration

So how do all these benefits come about? It’s quite simple. Imagine the compact belt filter as a filter coffee machine. Filtration is based purely on gravity. It takes time for the medium to pass through the process. The more contaminated medium there is, or the less that flows away, the more the filter fills up with medium, and the faster the float gives the signal to continue the belt’s cycle. This in turn leads to a relatively faster consumption of the nonwoven fabric, and with that to more frequent changes. In the case of Müller’s cascading filter system, the medium is firstly pre-filtered, and secondly is literally pushed through the elements. This results in a higher availability of the pure medium thanks to the large elements. And only from a certain differential pressure, i.e., when the filter cake is too impermeable, is the signal to change given.

Automatic filtration reduces operating costs and supports unmanned operation

The entry-level option, combiloop CL4 G-400, is a basic version with which the 400-l clean liquid tank does not necessarily have to have an automatic filter, but can alternatively be used with the less expensive cascading filter. The automatic filtration is essential for the full-flow filtration versions combiloop CL4 G-600 and CL4 G-800. However, both the CL4 G-400 and the two CL3 G versions can be fitted with the self-cleaning automatic filter. Self-cleaning automatic filtration is the ultimate in CL filtration, and is the optimum solution for medium and high levels of contamination. The automatic filter enables low-maintenance, reliable and sustainable operation.

// combiloop CL4 G-400 eco+ 70/60 with automatic filtration

// combiloop CL4 G-400 eco+ 70/60 with automatic filtration

eco+ dynamic power concept saves energy for lower costs

It is generally the case that the self-regulating eco+ piston pump is geared towards the maximum energy efficiency. It provides exactly the volume flow that is actually required. Thanks to the control effect, up to 26% of energy is saved, and significantly less heat passes into the medium. This results in higher temperature stability in the medium, which leads to improved, more uniform machining. The self-regulating eco+ piston pump also has an incredibly long service life and reduces both downtime and maintenance costs.

Predefined interfaces for fast, safe use

Thanks to close system partnerships with leading machine manufacturers and 20 years of plant engineering, we have predefined and tailor-made interfaces for a wide range of machines that enable the efficient interaction between high-pressure peripherals and lathes through smooth communication between machine control and machine.

| For retrofitting or upgrading your // processing machines, // multi-spindles, // sliding headstock automatic lathes or // turning/milling centres | by leading brands such as: Miyano, Doosan, Biglia, Winema, Scherer, ZPS-Slin/Manurhin/ Tajmac, Weisser, DMG Mori, Mazak, Tornos, Hanwha, Tsugami, Spinner, Benzinger, Schütte, Index, Traub, Nakamura, Okuma, Matsuura, Takamaz, CMZ, Hwacheon, Grob, Hermle, SW ... and many more! | |||

Compactness saves space for greater productivity and flexibility

The compactness, with simultaneous performance and high efficiency, results among other things from the intelligent, space-saving filtration concept as well as the pressure-controlled piston pump technology. The models combiloop CL3 G eco+ 50/45 and 70/40 measuring 1,300 x 600 x 1,100 mm (L x W x H) in particular are unrivalled in this field of application. These systems are mobile, and can also be used on a range of machines. The combiloop CL4 models, on the other hand, are stationary. However, with the clever technology built on the clean tank – and wonderful accessibility thanks to the door – the combiloop CL4 G-400 eco+ of with up to 60 l/min at 70 bar is a real space-saver.

In addition to all these individual aspects, which make the combiloop CL3 G eco+ 50/45 and 70/40 as well as the combiloop CL4 G-400 eco+ 70/60 true price-performance efficiency masters, there is also the overarching Müller CL high-pressure application benefit: lower unit costs and cost efficiency in machining.

// combiloop CL3 G eco+ 50/45 and 70/40

// combiloop CL3 G eco+ 50/45 and 70/40

Just convince yourself – with the unique Müller retrofitting campaign!

As part of an exciting retrofitting campaign, Müller customers have from now until 31 December 2021 to trial the CL4 G-400 eco+ 70/60, CL3 G eco+ 50/45 and 70/40 for 4 weeks with no obligation to buy. The only costs are an installation fee of 999 euros – which includes logistics and uninstallation if the product is not purchased! Richard Huber, Müller Sales manager, explains it: “Our aim is that potential new customers as well as our existing ones should benefit as precisely, quickly, easily and safely as possible from high flushing performances between 40 and 150 l/min at pressures of more than 30 bar. Hence this trial campaign with our highlights for high flushing performances. So together we are sending a clear signal in the fight against over-dimensioning and inefficiency at your existing plants!”

Would you like to know more? We will be happy to advise you! Contact us to arrange a consultation – online, over the phone or in person.